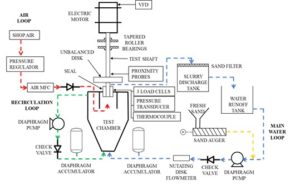

Electric Submersible Pumps (ESPs) increase head of process fluid in oil production from within the well. ESP mechanical failure most commonly results from severe vibrations in the pump section that increase in magnitude as interstage seal clearances increase. Interstage seals wear from the gas, liquid, and abrasives pumped through them. I studied the impact of different factors on interstage seal wear, leakage, and dynamic performance using the shown component-level test rig to simulate ESP operating conditions. The test rig has the capability to vary gas concentration, sand concentration, speed, rotor unbalance, and differential pressure.